For any angler, shopping for tackle should be a treat. There are so many new and exciting products out there to choose from — all promising to catch more fish.

But for any product to become viable, it has to go through extensive research and development. And the companies who perfect this process usually stand out.

I represent Rapala — the largest lure manufacturer in the world. They got that big because they put an emphasis on product development.

Since the time Lauri Rapala’s first Floating Minnow reached the bass market, the company has dedicated itself to perfection. Their product mantra has always been, “Hand-Tuned, Tank-Tested.”

Rapala reasoning

According to Rapala’s head lure designer, Mark Fisher, the key to success is good communication and an idea for a product that has a definite application.

“We’re constantly networking with our media partners, pro staff and sales force to find new areas of need,” shares Fisher. “And when something viable is presented, we then try to find some overlapping applications. For example, if it will catch bass here in the states, will it also catch barramundi in Australia, or pike in Europe? Obviously, the broader the appeal, the better.”

Fisher says if an idea sticks, the process of development can then begin — first with conceptual drawings by hand, then by computer or computer-aided design (CAD). During this phase, body shape and profile are determined, as well as the lure’s pull-point and hook configuration. Weighting is also considered, and that may include an internal weight-transfer system to aid in distance casting or balance during the retrieve.

Once the conceptual design is refined and agreed on, then the process of prototyping begins.

“There’s a tremendous amount of back and forth during this phase,” claims Fisher. “From Finland to Minneapolis, to our partners in the field and back again. Every new prototype receives exhaustive testing and evaluation.”

Rick Billings, Rapala’s VP of product development, works with Fisher throughout the process, claiming, “A lure has to perform exactly as desired or we won’t bring it to market.”

He also emphasizes the importance of each new product having a message. “Our sales and marketing teams need a story to tell. If they’re not onboard, then it’s not a productive use of our time. Engagement is essential, from our sales force all the way to the end consumer.”

Opposites attract

Although they work together, Billings and Fisher are vastly different in their approach.

“Fisher is the creative genius behind our P.D. effort,” shares Billings. “I’m more a spreadsheet, numbers guy. Math and engineering is my background. So, we’re coming from two entirely different directions, yet, we somehow find each other in the middle. And we’re in complete agreement when we get there.”

The pair’s unique synergy stems from more than just their contrasting personalities or working environment. Fisher and Billings are longtime tournament anglers, so they know how a lure has to perform in order to have any meaningful application. Their combined on-the-water experience also aids in visualizing new concepts.

“Take our Balsa Extreme (BX) Series, for example,” suggests Fisher. “The idea there was to take key aspects of proven materials and combine them to develop an entirely new concept in lure production. We both wanted to utilize the buoyancy characteristics of balsa, but develop it in a way that made the end product much more durable. So, we involved our engineers and they figured out how to encase balsa inside a tough, plastic shell. And that is how the BX Series was born.”

According to Billings, the concept took a while to find its legs. But by putting their time, energy and resources behind it, the BX product line now flourishes. And it’s this same commitment that brought success to other lure groups under the Rapala label — such as the X-Rap and Scatter Rap series.

Back to the drawing board

As prototyping progresses, other tasks require attention. Fisher begins his work on developing size and color variations, while Billings ensures product costs and schedules are hitting their targets.

Packaging is also considered, the graphics for which are done in house at Rapala. Serving as their VP of global creative, Bob Bussey makes sure all packaging concepts and designs accent the quality of the lures they contain.

Bussey’s team also works on catalog sheets and advertising material, which will accompany those products headed for market. It’s a laborious effort, but one that is essential to the process. And all of this is happening as prototyping is underway.

Focus on the future

Looking ahead, both Fisher and Billings face challenges. But none that won’t be met with the same desire and ambition to succeed.

“Each year we’re tasked with keeping the product line fresh,” Billings says. “But at the same time, we want the lures we introduce to have certain and immediate application … over multiple markets, for a variety of species. Our preferred strategy is to develop and expand product families over a period of time as opposed to churning out a bunch of stand-alone, one off type products.”

Fisher feels it’s also critical they attract future generations of anglers to Rapala. “Younger anglers, who are perhaps less familiar with our various brands, are a constant concern. Things move so fast in today’s market, keeping in touch with the next generation takes an open mind and quick reflexes. And to pull that off while maintaining product integrity is a challenge.”

The two share one other conviction. They believe no new lure should ever make an earlier lure in the Rapala family obsolete. Instead, it should build upon those that preceded it. It’s another thing that separates Rapala from other brands.

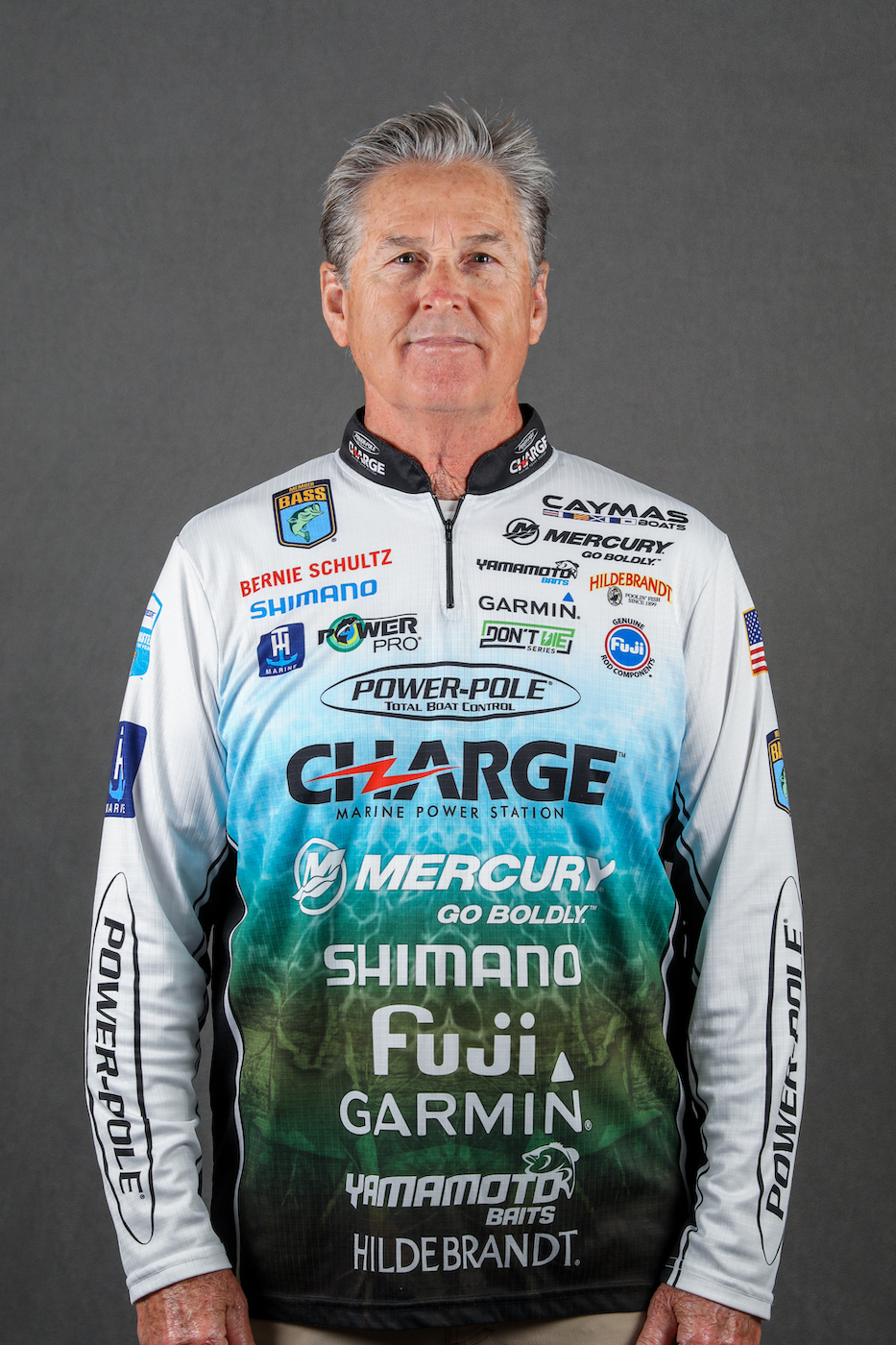

Follow Bernie Schultz on Facebook or through his website. More on Rapala.